— Your Prime Source for Advanced Relays And Water Valves —

Product Overview

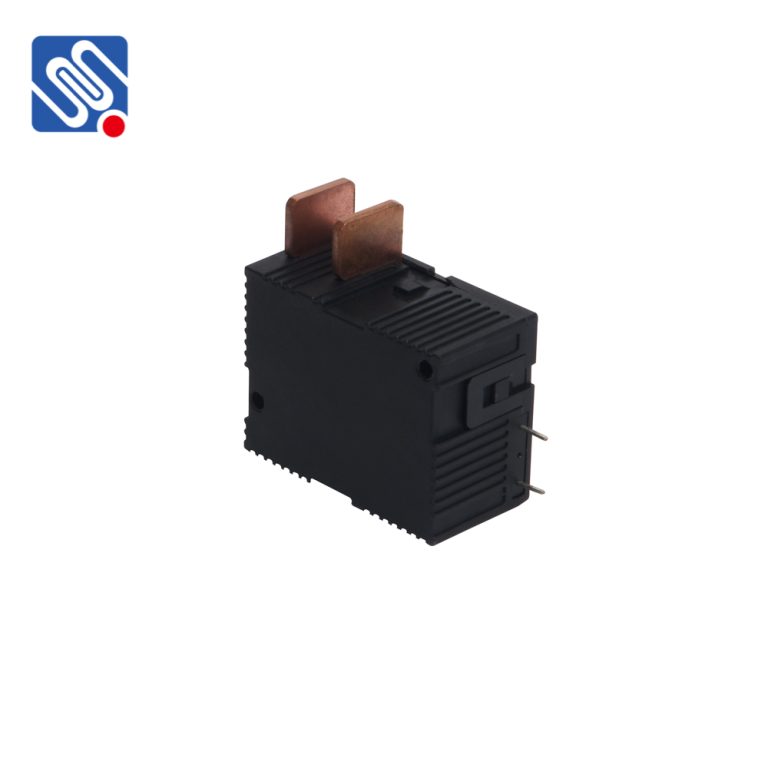

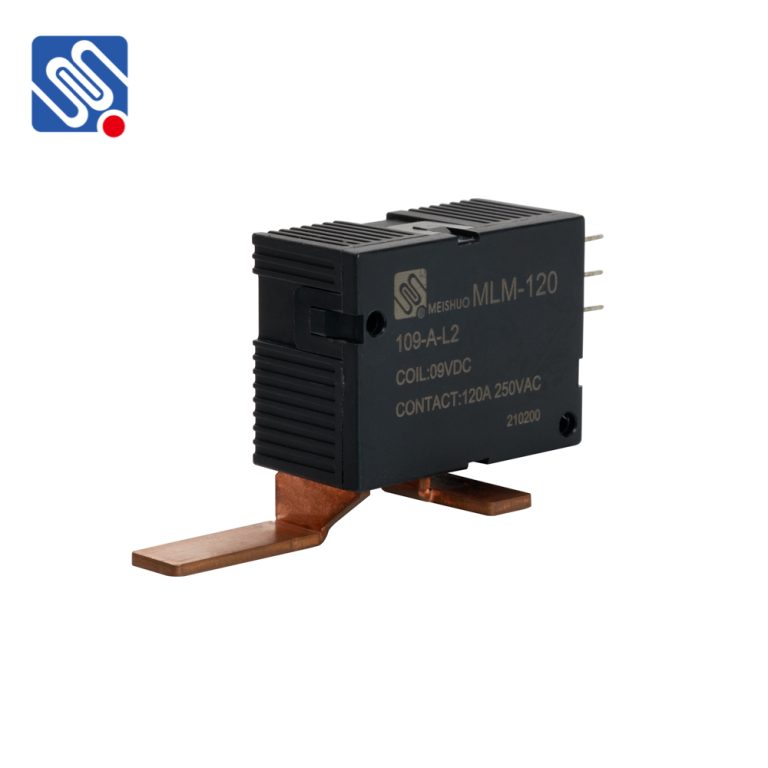

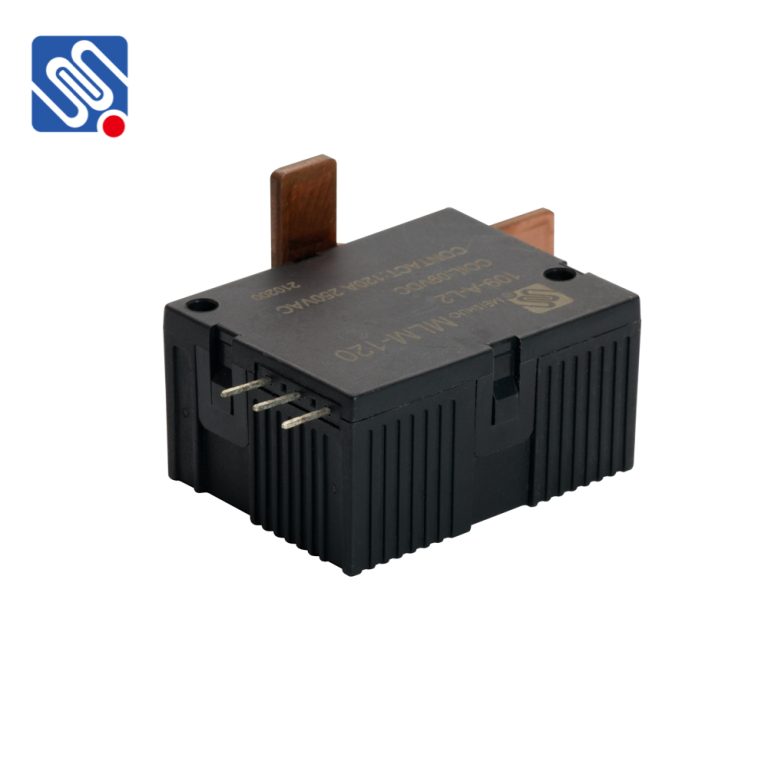

The MLM relay has a contact switching capability of 120A and can weld accessories according to customer needs. The normally open and normally closed states of the MLM relay are completely provided by permanent magnet steel, and the switching state is completed based on triggering a pulse signal of a certain width.

Contact Parameters

| Contact Form | 1A,1B |

| Contact Material | Silver Alloy |

| Contact Resistance | ≤1mΩ(1A 6VDC) |

| Contact Rating | 120A 250VAC |

| Max. Switching Current | 120A |

| Max. Switching Voltage | 250VAC |

| Max. Switching Power | 30KVA |

| Electrical Life | 10000 OPS |

| Mechanical Life | 100000 OPS |

Characteristics

| Insulation Resistance | 1000MΩ Min. (500VDC) |

| Dielectric Strength | Between Coil&Contacts: 4000VAC 1min |

| Between Open Contacts: 2000VAC 1min | |

| Set Time | ≤20ms |

| Reset Time | ≤20ms |

| Shock | Functional: 98m/s² |

| Destructive: 980m/s² | |

| Vibration | 10Hz~55Hz 1.5mm(DA) |

| Humidity | 45%~90%RH |

| Ambient Temperature | -40℃~+85℃ |

| Construction | Dust Protected |

| Unit Weight | Approx.75g |

Naming Rules

Model: MLM

Load: 120A

Contact Group: 1 Group

Coil Voltage: 06, 09, 12, 24VDC

Contact Form: 1A, 1B

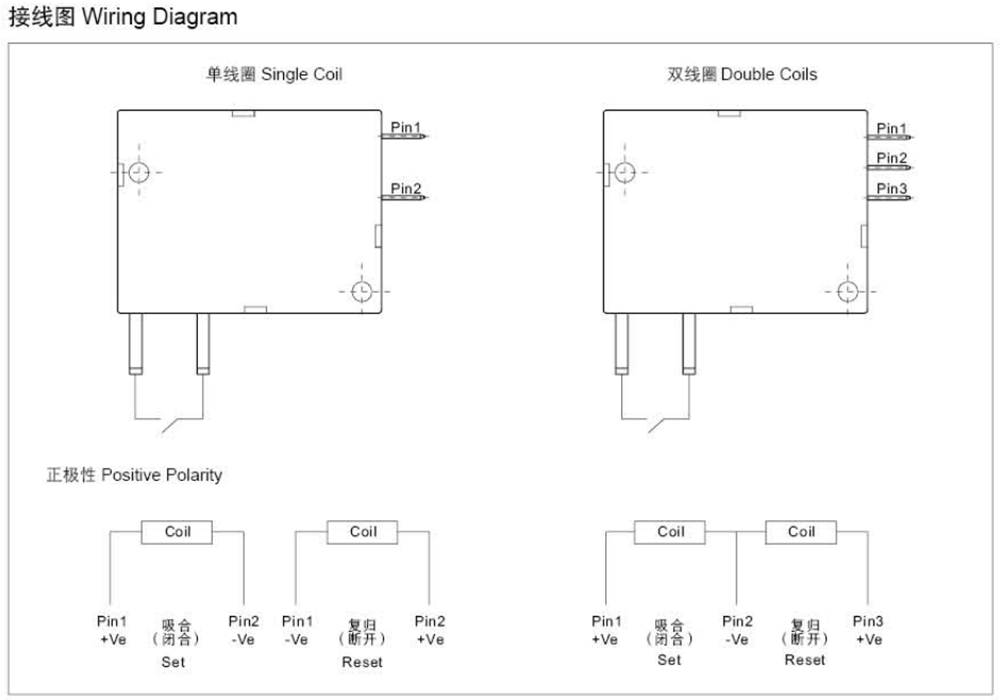

Coil Type: L1: Single Coil Latching L2: Double Coils Latching

Polarity: R: Negative Polarity Nil: Positive Polarity

Special Code: XXX: Customer Special Requirement

Application

Smart grid: Used for monitoring,regulation,and protection of power systems.

Smart meters: IC card meters, prepaid meters, single-phase meters, three-phase meters.

Reactive power compensation: synchronous switch, composite switch, smart capacitor.

Company Profile

Zhejiang Meishuo Electric Technology Co., Ltd. is a high-tech enterprise specializing in the production of various electromagnetic water valves and relays. The company was established in 2007.The company has excellent equipment and advanced technology, using automated assembly line operations and complete testing equipment to ensure consistency and accuracy of performance. At the same time, we have strong production technology and development capabilities, with product testing centers and material testing centers to ensure product quality.

Production Workshop Display

The production workshop adopts dust-free control and constant temperature and humidity environment to improve the reliability of products. Very strict in terms of quality control, from raw material procurement to finished product delivery, every process undergoes rigorous quality testing and screening.

Exhibition

Support your OEM/ODM needs and provide one-stop customized solutions