When choosing solenoid valves for industrial use, the two common choices—galvanized electroplated and color electroplated valves—have distinct advantages depending on the application. Here’s a brief overview to help guide your purchase decision.

1.Environmental Standards: Galvanized Electroplated is Preferred

Galvanized electroplated valves meet ROHS (Restriction of Hazardous Substances) standards, which is essential for global compliance. These valves are free of hazardous substances, making them suitable for regions with strict environmental regulations.

On the other hand, color electroplated valves may pass initial ROHS tests, but the protective layer tends to break down under harsh conditions like high temperature or humidity, causing non-compliance over time.

2.Corrosion Resistance: Galvanized Wins for Durability

Galvanized electroplated valves offer good corrosion resistance, and this can be further improved with enhanced coatings and packaging. These valves are ideal for long-term, reliable performance, especially when properly packaged to protect against moisture or saltwater during transportation.

Color electroplated valves, while effective initially, lose their protective coatings over time, especially in harsh environments, making them less durable.

3.Packaging Considerations

The packaging of galvanized electroplated valves is crucial to ensure they remain corrosion-free during shipping. Proper packaging prevents exposure to environmental factors like moisture and salt.

Color electroplated valves, despite good packaging, still face higher risks of corrosion if their protective coating deteriorates during transport.

4.Long-Term Value

Although color electroplated valves might perform well in the short term, their protective coatings are not as durable as those on galvanized electroplated valves. Galvanized electroplated valves, with proper surface treatment, provide a more reliable, cost-effective solution for long-term use.

Conclusion

Galvanized electroplated valves are a better choice overall for industries that need long-term reliability, environmental compliance, and enhanced corrosion resistance. Color electroplated valves may be suitable for less demanding environments but fall short in extreme conditions. When purchasing, always consider the valve’s material, environmental standards, and packaging for optimal performance.

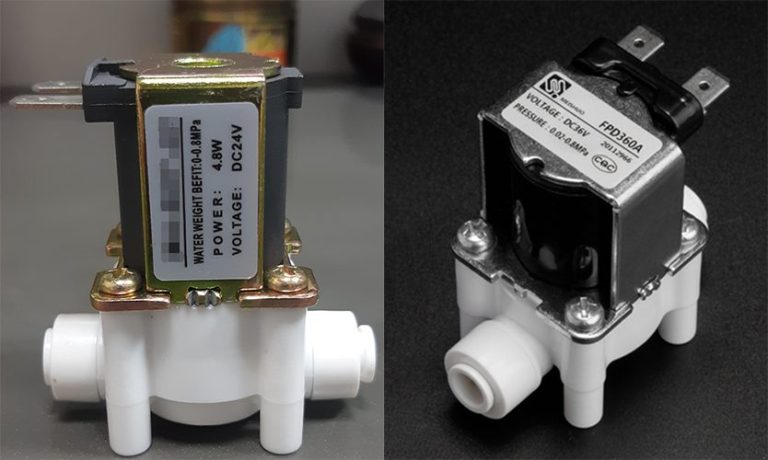

Colourful plating Galvanic plating