Automotive Relays

In modern vehicles, relays play a crucial role. They not only enhance the stability and reliability of the vehicle’s electrical system but also ensure the proper functioning of various components. Automotive relays manage electrical current to control multiple parts of the vehicle, including the engine, air conditioning, lighting, security systems, and more. This article will provide a detailed introduction to automotive relays, covering their principles, applications, specifications, CE certification requirements, quality, and product recommendations, to help international customers better understand this essential component.

*The Principle of Automotive Relays

A relay is an electrical switch that controls high-current circuits using a low-current electrical signal. Automotive relays primarily consist of an electromagnet, contacts, and springs. When current passes through the electromagnet, a magnetic field is generated, which pulls or releases the contacts, allowing or interrupting the flow of electrical current. This process is triggered by the vehicle’s control system and responds quickly to ensure that high-current circuits do not directly affect other sensitive components.

*Applications of Automotive Relays

-

Engine Start System: Relays are widely used in automotive engine start systems to control the switch of the starting current, ensuring smooth engine startup.

-

Air Conditioning System: Modern automotive air conditioning systems often rely on relays to control the activation and deactivation of the compressor. The relay ensures the proper flow of current and prevents electrical short circuits or overloads.

-

Lighting and Power Windows: Automotive lighting systems, power windows, and seat adjustment systems also use relays for control. Relays protect circuits and extend the lifespan of these components.

-

Security Systems: Automotive electronic security systems (such as alarms, remote start systems, etc.) rely on relays to manage the current, ensuring the system operates reliably in various conditions.

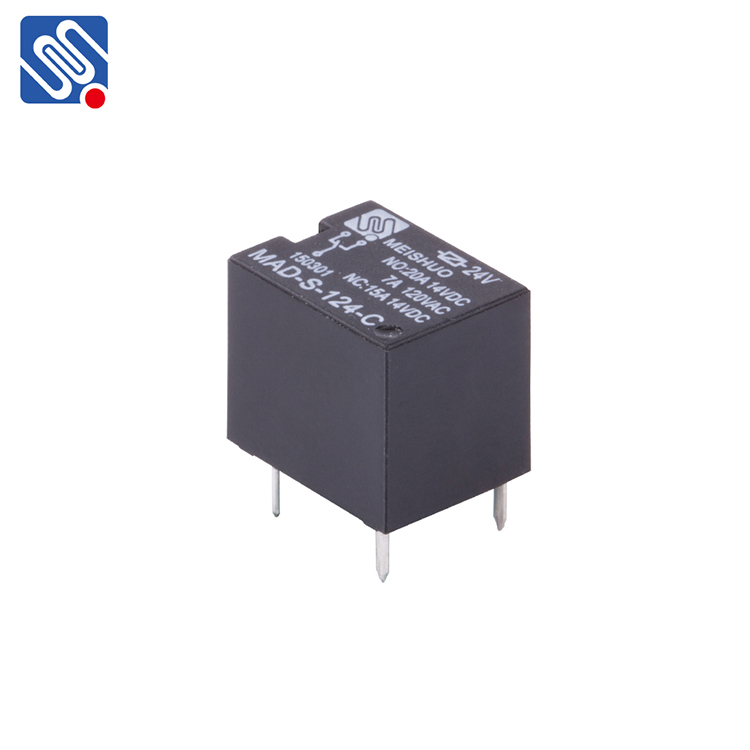

*Key Specifications of Automotive Relays

When selecting automotive relays, it is important to understand their key specifications. Common specifications include:

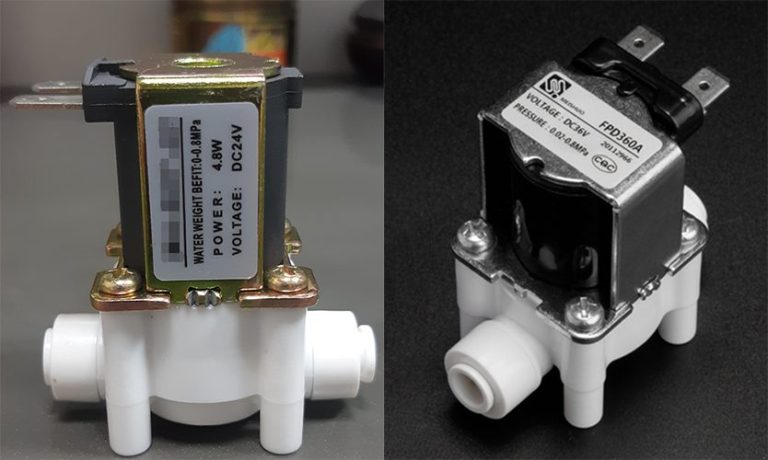

- Rated Voltage: Typically 12V or 24V to suit different vehicle types.

- Rated Current: This is usually selected based on the load being controlled, with common ratings including 10A, 20A, 30A, etc.

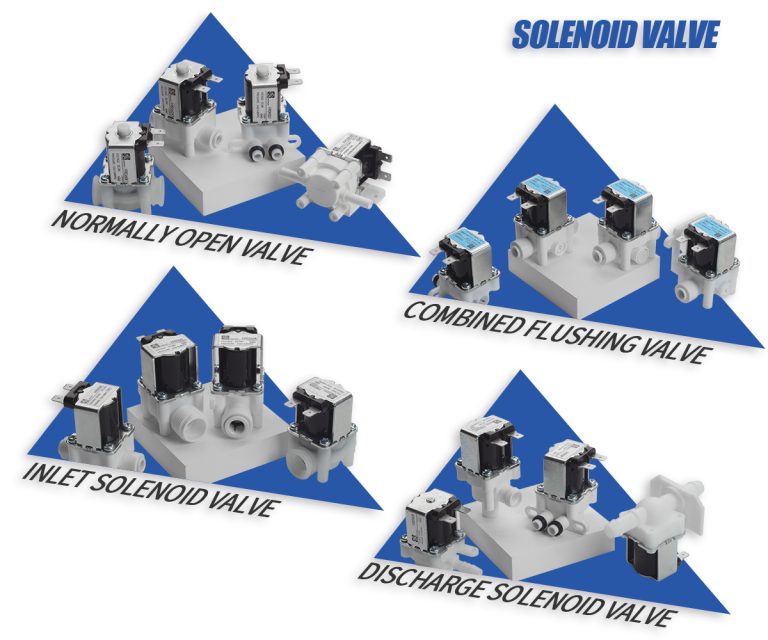

- Contact Type: Includes Normally Open (NO), Normally Closed (NC), and Changeover contacts, with the type chosen based on the circuit requirements.

- Dielectric Strength: Refers to the maximum voltage the relay can withstand, usually indicated in the product specifications.

- Response Time: The time it takes for the relay to react, typically in milliseconds.

Understanding these specifications helps customers choose the right relay product to meet the needs of different vehicles, ensuring stable and safe electrical system performance.

*CE Certification: Requirements for Compliance

To sell automotive relays in the European market, obtaining CE certification is essential. CE certification confirms that the product meets EU safety, health, and environmental standards. The key requirements include:

- Compliance with EU Directives: The relay must conform to specific European Union directives, such as those related to electromagnetic compatibility (EMC) and safety.

- Testing: The product must pass tests for electrical, thermal, and mechanical performance to ensure it meets EU safety standards.

- Declaration of Conformity: The manufacturer must provide a Declaration of Conformity, confirming that the relay meets all relevant EU regulations.

CE certification is critical for ensuring that automotive relays are both safe and reliable for use in the European automotive market.

*Quality Control of Automotive Relays

Quality is a top priority for customers when selecting automotive relays. As a critical electrical component, the reliability of a relay directly impacts the overall performance and safety of the vehicle. Therefore, high-quality relays must be manufactured with precision and undergo strict quality checks. Common quality control measures include:

- High and Low Temperature Testing: Ensures the relay operates reliably in extreme weather conditions.

- Vibration Testing: Simulates the vibrations experienced by a vehicle during operation to ensure the relay’s durability.

- Electrical Performance Testing: Tests the relay’s electrical properties, such as the conductivity of contacts and stability during operation.

*Product Recommendations

When choosing automotive relays, overseas customers often consider factors such as brand reputation, performance, certification, and price. We recommend our high-quality automotive relays, which are CE certified and comply with international standards. Made from heat-resistant and corrosion-resistant materials, our relays perform reliably in various harsh environments. Whether for traditional internal combustion engine vehicles or electric vehicles (EVs), we offer suitable relay solutions to enhance the safety and efficiency of electrical systems.

Conclusion

As a core component in automotive electrical systems, the quality and performance of relays directly affect the vehicle’s safety and reliability. With the continuous growth of the global automotive industry, the demand for automotive relays is increasing. We are committed to providing overseas customers with high-quality, CE-certified automotive relays to improve vehicle performance and reliability. Contact us today for more product details and customized solutions.