Introduction

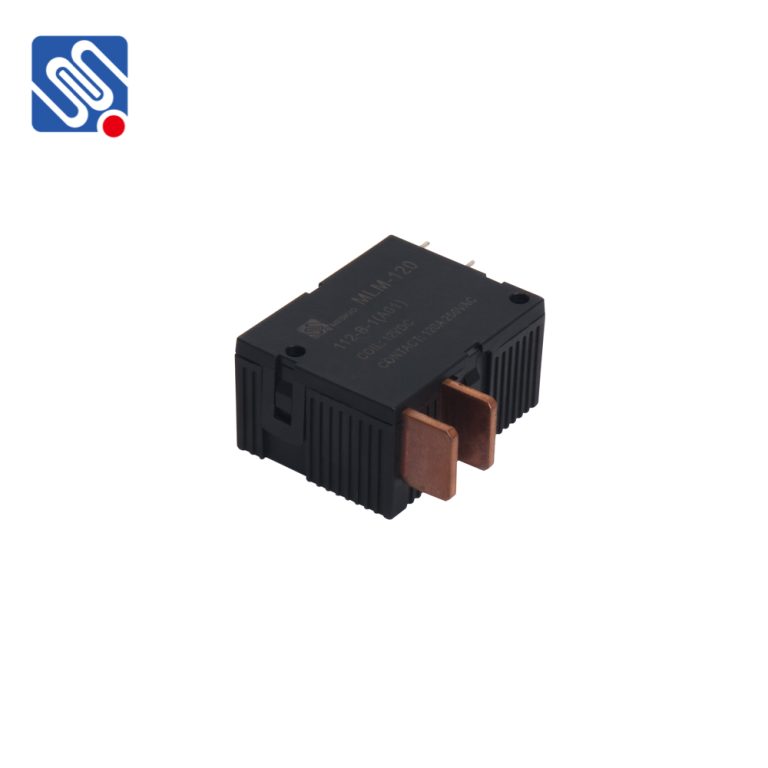

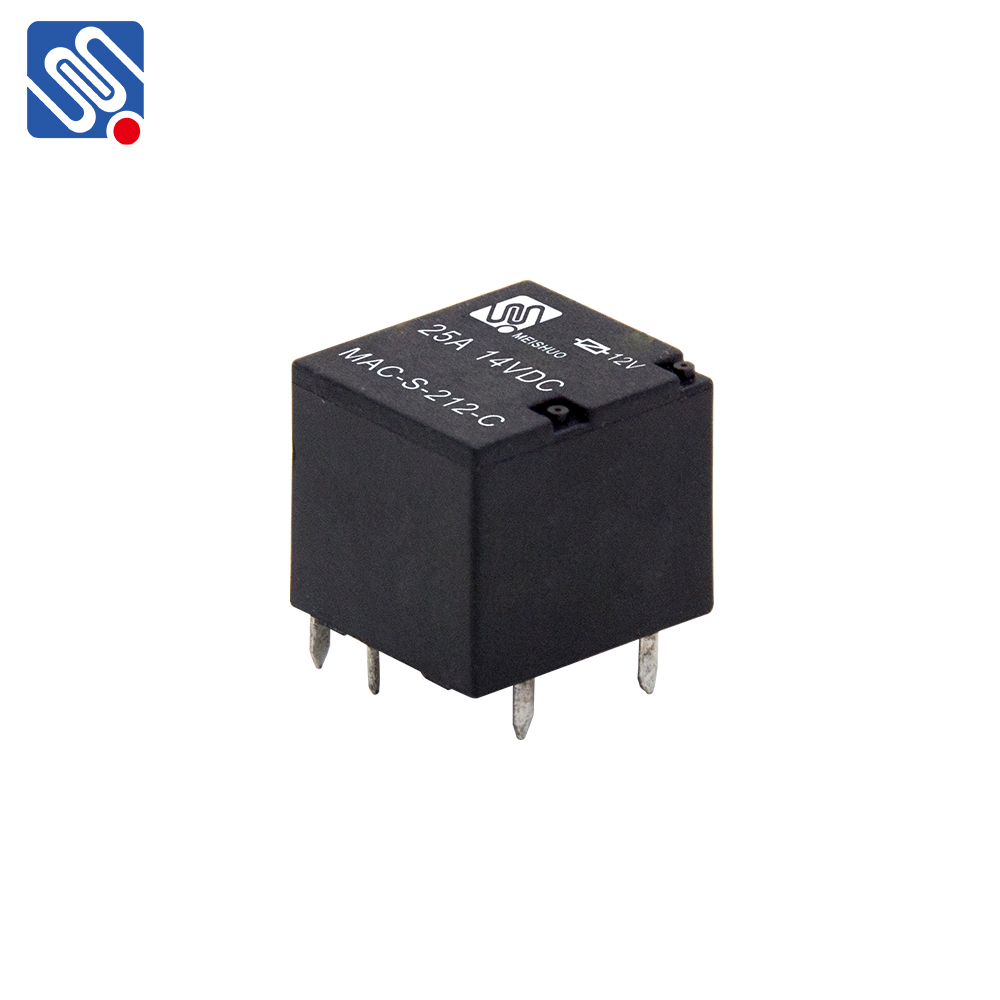

Relay performance heavily depends on contact materials, which directly impact electrical conductivity, durability, and resistance to arcing. While traditional materials like pure silver, copper, or silver-cadmium (AgCd) have been widely used, silver alloy contacts are now leading the industry due to their superior performance. At MEISHUO, we utilize high-performance silver alloy in our relays, ensuring longer lifespan, lower contact resistance, and enhanced reliability for demanding applications. The Evolution of Relay Contact Materials

1.Pure Silver (Ag)

The Evolution of Relay Contact Materials

1.Pure Silver (Ag)

The Evolution of Relay Contact Materials

1.Pure Silver (Ag)

The Evolution of Relay Contact Materials

1.Pure Silver (Ag)

- High conductivity but prone to welding and oxidation.

- Limited lifespan in high-current switching.

- Better arc resistance than pure silver.

- Cadmium is toxic, leading to environmental restrictions (RoHS compliance issues).

- Excellent arc resistance and anti-welding properties.

- Used in high-load applications like automotive and industrial systems.

- Superior conductivity and mechanical strength.

- Lower contact resistance than pure silver or oxide-based materials.

- Enhanced resistance to erosion and material transfer, extending relay lifespan.

- Automotive – EV charging, battery management systems.

- Industrial Automation – PLCs, motor controls, and power distribution.

- Renewable Energy – Solar inverters and wind turbine controls.

- Smart Home & IoT – Reliable switching in smart appliances.