Relays are the unsung heroes in countless electrical systems, working tirelessly behind the scenes. Yet, like any hardworking component, they’re not immune to problems. One of the most common issues? Sticky relay problems. Yes, it’s as frustrating as it sounds—like when your favourite playlist skips a song halfway through. But why does it happen, and more importantly, how can you solve it? Let’s dive in.

5.Reduce Overloads

Overloads are a major sticking trigger. To prevent this:

Use current-limiting devices like circuit breakers or fuses.

Avoid running equipment beyond its designed capacity.

5.Reduce Overloads

Overloads are a major sticking trigger. To prevent this:

Use current-limiting devices like circuit breakers or fuses.

Avoid running equipment beyond its designed capacity.

What Is Relay Sticking?

Let’s keep it simple. Relay sticking happens when the relay contacts become stuck together, either permanently or intermittently. Instead of opening and closing like they’re supposed to, the contacts remain welded or jammed. This can lead to all sorts of problems, from equipment malfunctions to total system failures. If you’re running industrial machines, household appliances, or even car electronics, relay sticking can throw a massive wrench in the works.Why Do Relays Encounter Sticking Problems?

It’s not a one-size-fits-all answer. There are a few reasons why your relay might decide to misbehave. Here are the most common culprits: 1.Excessive Current or Overload Imagine trying to carry a box that’s way heavier than you expected. It’s the same for your relay. If the current exceeds the relay’s capacity, it can cause the contacts to overheat and stick together. Example: Think about relays in air conditioners or refrigerators. These appliances often cycle heavy loads, and if the relay isn’t rated for the job, it’s like asking a small car to tow a truck. 2.Contact Material Wear Relay contacts aren’t invincible. Over time, they can degrade due to: Arcing: When the contacts open or close, a tiny spark (arc) forms, gradually eroding the surface. Oxidation: Environmental factors can cause a layer of oxidation to form, which weakens the contacts. Pro Tip: If you notice your relay sticking after long periods of use, it might just be wear and tear. 3.Environmental Factors Your relay isn’t a fan of extreme conditions. Dust, humidity, or high temperatures can wreak havoc. Dust particles can lodge between the contacts, while moisture can accelerate corrosion. 4.Inductive Loads When relays handle inductive loads (like motors or solenoids), the collapsing magnetic field generates voltage spikes. These spikes can cause arcing or even weld the contacts together. 5.Cheap or Improper Relays Using a low-quality relay or one that’s not designed for your application is asking for trouble. Always match the relay’s specifications to your system’s needs.How to Identify Relay Sticking Problems

Spotting relay sticking early can save you from bigger headaches. Here’s how to tell if your relay is acting up: 1.Symptoms of a Stuck Relay Equipment fails to turn on or off: If your device stays powered when it shouldn’t, or refuses to start, the relay could be stuck. Burnt smell: Sticking often comes with overheating, which can produce a noticeable burnt odour. Intermittent behaviour: The system might work one minute and fail the next. 2.Testing a Relay To confirm the issue: Use a multimeter to test continuity across the contacts. Disconnect the relay and inspect it visually. Welded contacts or burn marks are dead giveaways.Solutions to Prevent and Fix Relay Sticking

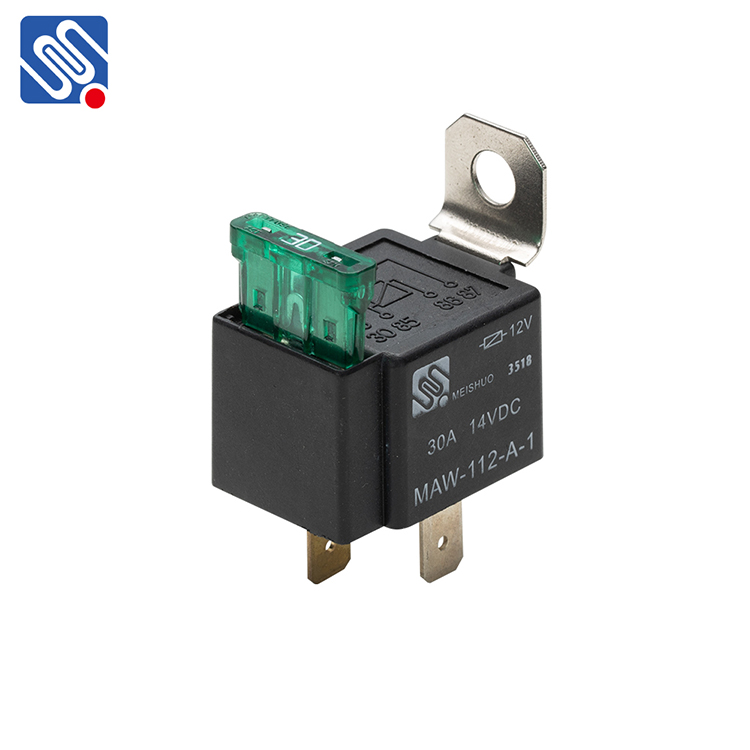

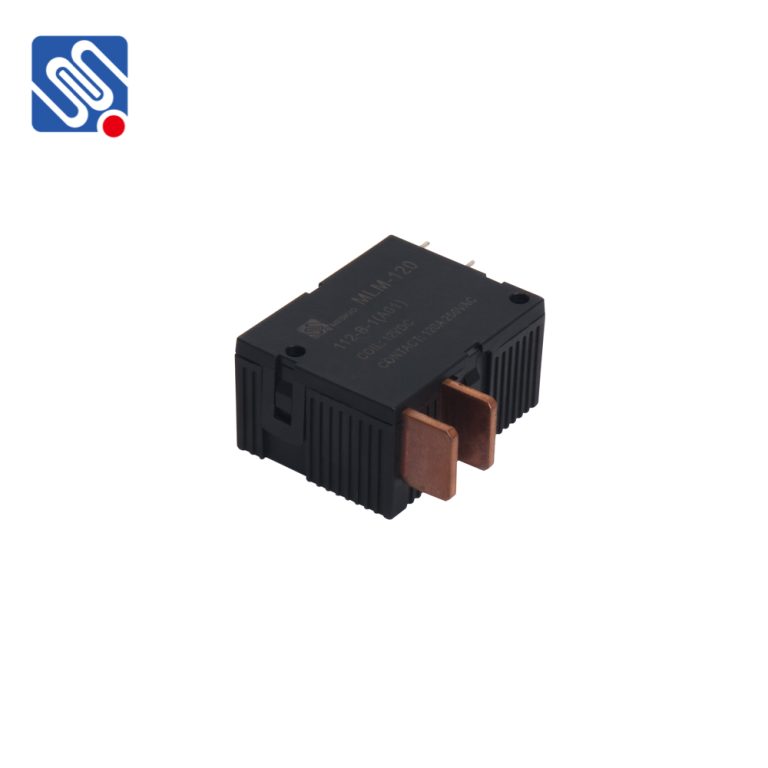

Now for the good stuff—how to deal with relay sticking. Whether you’re trying to prevent it or fix an existing issue, these tips have got you covered. 1.Choose the Right Relay This is your first line of defence. Make sure your relay is: Rated for your system’s voltage and current. Designed to handle specific loads (inductive, resistive, or capacitive). Example: If you’re working with heavy-duty motors, go for a relay that can handle high inrush currents without breaking a sweat. 2.Use Snubber Circuits A snubber circuit is like a cushion for your relay. It absorbs voltage spikes from inductive loads, reducing the chances of arcing and sticking. For AC circuits: Use an RC snubber (resistor + capacitor). For DC circuits: Try a freewheeling diode across the inductive load. 3.Regular Maintenance Keep your relays happy by: Cleaning the contacts: Use a contact cleaner to remove dirt and oxidation. Checking for wear: Replace relays showing signs of damage or corrosion. 4.Upgrade to Solid-State Relays (SSRs) If mechanical relays keep giving you grief, consider switching to solid-state relays. They don’t have physical contacts, so sticking isn’t an issue. Plus, they’re faster and quieter. 5.Reduce Overloads

Overloads are a major sticking trigger. To prevent this:

Use current-limiting devices like circuit breakers or fuses.

Avoid running equipment beyond its designed capacity.

5.Reduce Overloads

Overloads are a major sticking trigger. To prevent this:

Use current-limiting devices like circuit breakers or fuses.

Avoid running equipment beyond its designed capacity.