No posts found

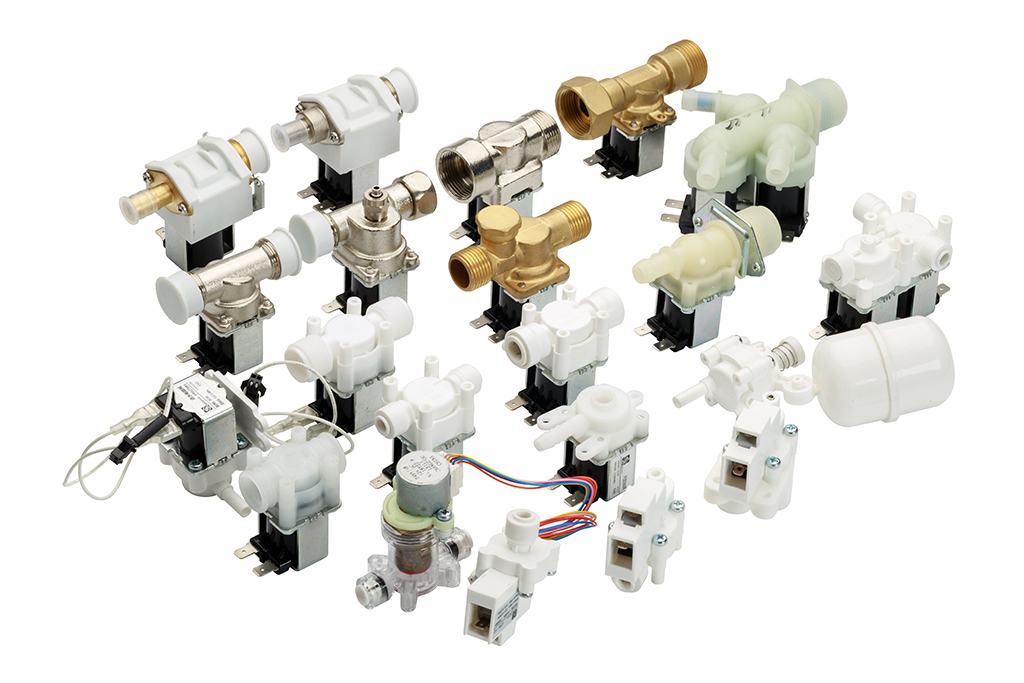

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Commitment to Excellence in Production

Commitment to Excellence in Production

Flushing Solenoid Valves are automated component used to control the on and off of fluids (such as water, gas, etc.). It is usually composed of electromagnetic coils, valve cores, valve seats and other components. The electromagnetic coil is energized to generate a magnetic field, which attracts the valve core to move, thereby realizing the opening and closing of the valve to control the flow of fluids and achieve functions such as flushing.

Flushing solenoid valves can be used with various equipment that require flushing functions, such as industrial cleaning machines, sewage treatment equipment, reverse osmosis pure water equipment, agricultural irrigation systems, household water heaters, etc. It can be used in conjunction with PLC control systems, sensors, etc. to achieve automated flushing process control, and accurately control the flushing time, frequency and flow rate according to different process requirements and conditions.

Avoid installing in environments with large vibrations, high temperatures, humidity, or corrosive gases. During installation, pay attention to the direction and slope of the pipeline to facilitate fluid discharge. At the same time, reserve enough space for the inspection and replacement of the solenoid valve. In addition, ensure that the pressure and flow in the pipeline are within the rated range of the solenoid valve to avoid overpressure or overflow operation.

In winter, it is necessary to prevent the medium from freezing and causing damage to the valve. For the medium that may freeze, insulation measures can be taken, such as wrapping with insulation materials or using heating devices. When the equipment is shut down, the medium in the valve and pipeline should be emptied in time to prevent the residual medium from freezing. In addition, low temperature may affect the electromagnetic performance of the solenoid valve and the flexibility of the valve core. The power supply voltage can be appropriately increased or the solenoid valve can be preheated.

General flushing solenoid valves are suitable for flushing clean media such as water, air, and oil. For corrosive media, it is necessary to select solenoid valves made of corrosion-resistant materials, such as stainless steel, polytetrafluoroethylene, etc. For media containing particulate impurities, solenoid valves with anti-clogging structures or large diameters should be selected to prevent impurities from clogging the valve core or affecting the normal operation of the valve.

The service life of the flushing solenoid valve is affected by many factors, such as frequency of use, working environment, medium properties, etc. Under normal use conditions, the service life of a flushing solenoid valve with good quality can reach tens of thousands of times or even higher. However, if it is used frequently in harsh environments, its service life may be greatly shortened. The service life of our products reaches ≥100,000 times OPS.

First, check whether the seals are damaged, such as the valve seat seal ring, valve core seal ring, etc. If damaged, they need to be replaced in time. Secondly, check whether the pipe connection parts are loose. If they are loose, they need to be tightened. If the leakage is caused by the wear of the valve core, the valve core or the entire solenoid valve may need to be replaced.

Noise may be caused by valve core vibration, loose electromagnetic coil or unstable medium flow. Check whether the valve core is firmly installed. If it is loose, tighten it. For the electromagnetic coil, check whether its iron core has impurities or wear. If so, clean or replace it. At the same time, optimize the pipeline layout to reduce the impact and vibration of the medium flow. You can also install noise reduction equipment such as mufflers at the inlet and outlet of the solenoid valve.

Clean the exterior of the solenoid valve regularly to remove dust, oil and other impurities. Check whether the connection parts are loose, and tighten them in time if they are loose. Check the status of the valve core and seals at regular intervals, clean them in time if there are impurities, and replace them in time if they are worn or damaged. For solenoid valves that are used for a long time, lubricants can be added appropriately to ensure smooth movement of the valve core.

You can use a multimeter to measure the resistance of the electromagnetic coil. If the resistance value is significantly different from the rated value, it means that the coil may be damaged. You can also observe whether the coil has obvious signs of damage such as burning or short circuit.

Our company was founded in 2007 and successfully went public in 2023, dedicated to developing innovative solutions for relays and water valves.

We accept various payment methods including credit cards, bank transfers, and AliPay.

You can purchase through our website or by contacting our sales team.

Yes, we provide a range of benefits including health insurance, paid leave, accommodation, and employee training.

Employees are entitled to paid annual leave, sick leave, and statutory holidays. The specific vacation policy may vary based on factors such as length of service and position.

If your product encounters any issues or damages, we offer product repair as well as professional technical support and training.

The product warranty period varies depending on the specific product type, but generally, it is a one-year warranty period.

We offer services including free sample delivery, product customization and development, printing customization, and packaging customization.

If you receive damaged or lost goods during transit, we will promptly contact the logistics company and assist you with the claims process. Please ensure to inspect the integrity of the goods upon receipt and promptly report any issues to us.

We strive to deliver orders on time, but in certain circumstances, unavoidable delays may occur, such as issues with raw material supply or production process adjustments. If there’s a delay in delivery, we will promptly notify you and provide appropriate solutions, such as expediting production schedules or offering compensation.

Support your OEM/ODM needs and provide one-stop customized solutions