No posts found

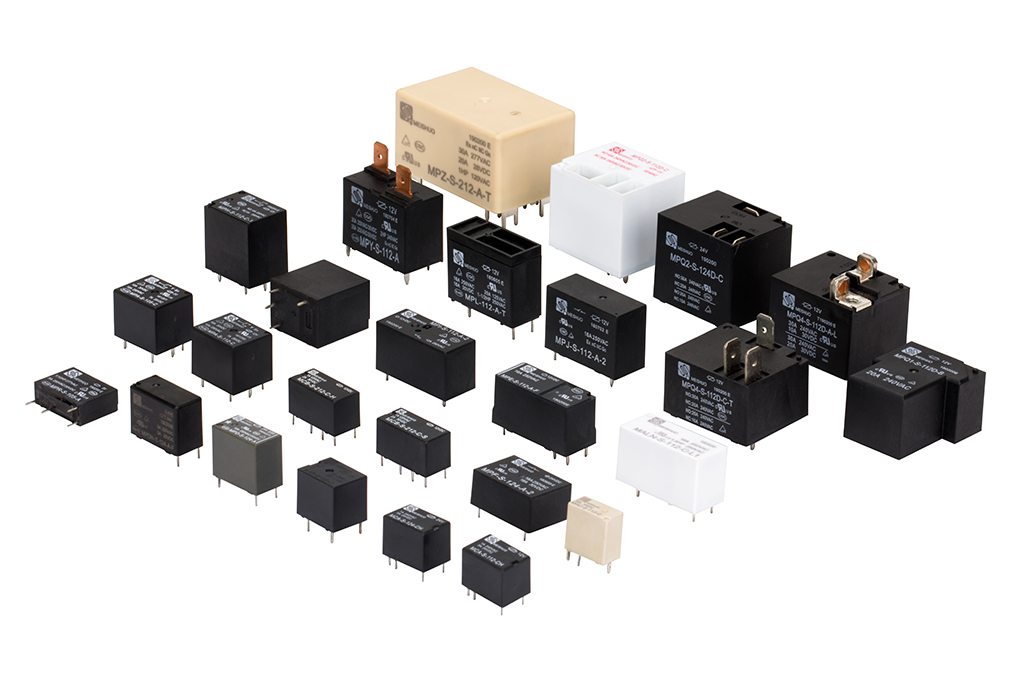

With 17 years of production experience, Meishuo is one of China’s top three relay manufacturers.

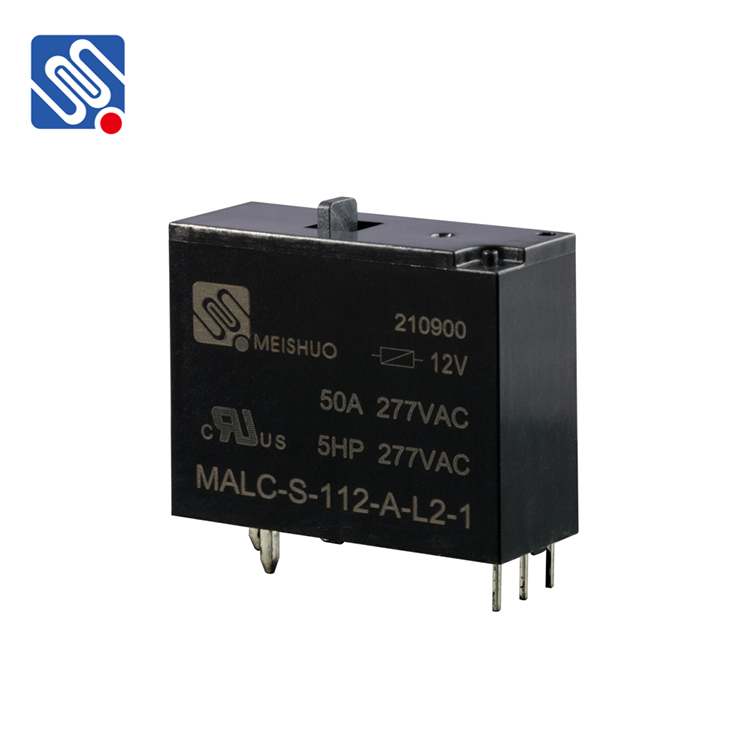

We focus on the development and manufacturing of a wide range of relays, including industrial, automotive, latching, new energy, signal, and general relays. We operate under the guiding principle of “Quality First, Customer Supreme.”

Every one of our products is certified by UL, TUV,CQC, and VDE, guaranteeing dependable quality and gaining our clients’ trust.

With 17 years of production experience, Meishuo is one of China’s top three relay manufacturers.

We focus on the development and manufacturing of a wide range of relays, including industrial, automotive, latching, new energy, signal, and general relays. We operate under the guiding principle of “Quality First, Customer Supreme.”

Every one of our products is certified by UL, TUV,CQC, and VDE, guaranteeing dependable quality and gaining our clients’ trust.

Commitment to Excellence in Production

Commitment to Excellence in Production

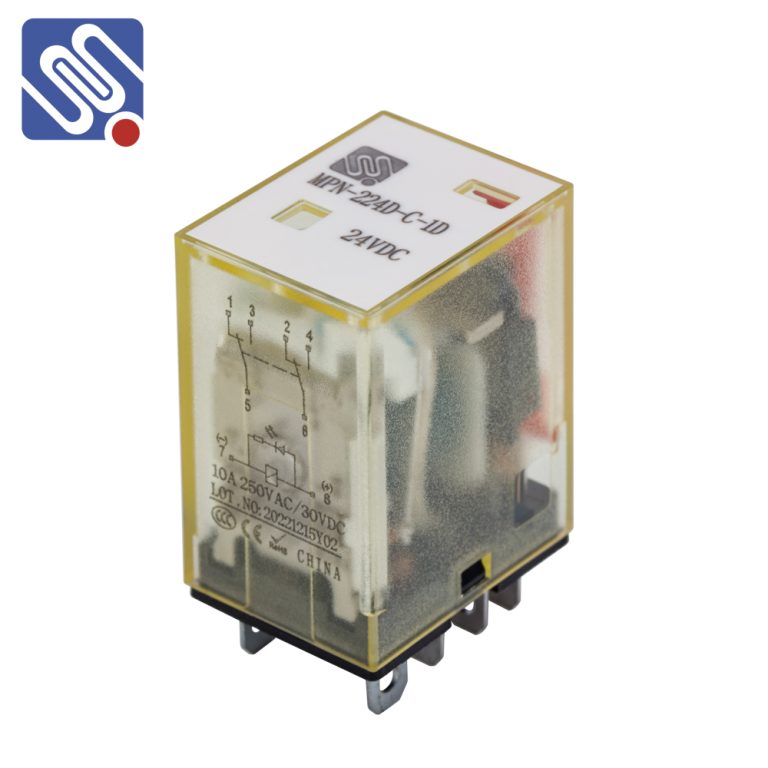

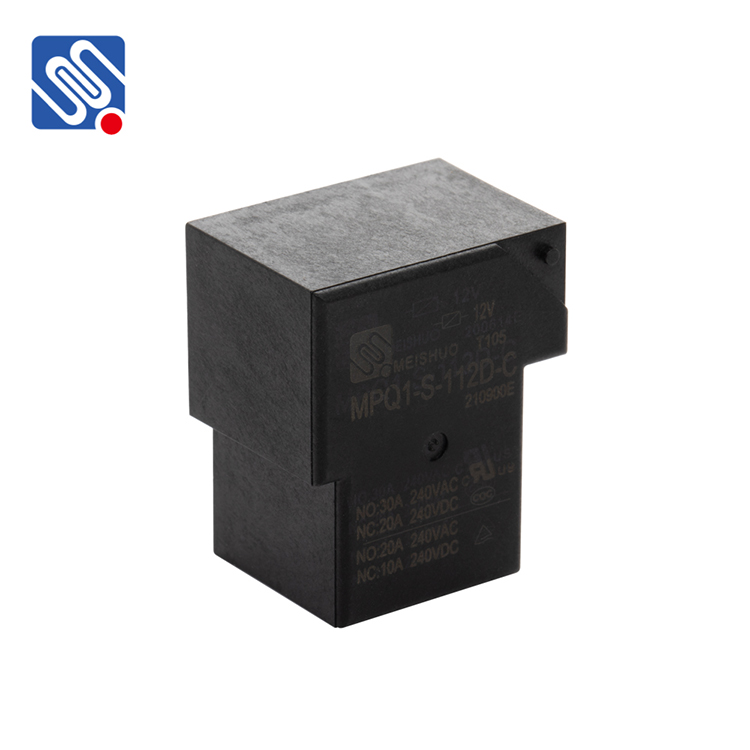

A PCB relay is an electronic device used as a switch to control the flow of electricity. It activates an internal electromagnetic coil with a low-power control signal, creating a magnetic field that moves a component to open or close contacts. PCB relays are widely used in applications like telecommunications, automotive systems, industrial machinery, and home appliances. Designed to be mounted directly onto a PCB, they save space and simplify circuit design, making them ideal for remote control and automation in electronic devices.

A PCB relay usually consists of an electromagnetic coil, a set of contacts and a mechanical device. When current passes through the coil, it generates a magnetic field, which acts on the contacts, causing them to attract or repel, thus switching the circuit. Through this process, the relay is able to effectively control the flow of current.

The main difference between PCB relays and other types of relays is the mounting method and size.PCB relays are designed to be mounted directly onto printed circuit boards, are small and easy to integrate, and are mostly used in household appliances where space is limited. Other types of relays, on the other hand, usually require external connections or additional mounting components and are larger in size for applications such as industrial or automotive applications that require more power control.

Load Requirements: Choose a relay that matches the appliance’s operating voltage and current, ensuring it can handle inrush current.

Operating Environment: Ensure the relay is suitable for the appliance’s temperature, humidity, and pollution conditions.

Reliability and Lifespan: Opt for relays with long mechanical and electrical lifespans and high reliability.

Size and Installation Method: Ensure the relay’s size and installation method fit within the appliance’s internal space.

Certification and Quality Standards: Make sure the relay meets international certifications to ensure safety and compliance.

Special Requirements: Select relays that meet specific appliance needs, such as waterproof, corrosion-resistant, etc.

For through-hole relays, check if the pad design matches the relay pin requirements. Then, insert the pins into the pads, solder using a soldering iron and solder. Finally, ensure the solder joints are smooth and free of short circuits, and confirm the soldering quality.

The lifespan of a relay is affected by factors such as temperature, humidity, pollution, and electrical load. For example, high temperatures accelerate the aging of internal materials; humidity and pollutants can cause contact corrosion or poor contact; frequent switching operations also accelerate contact wear, and so on. These factors all shorten the relay’s service life.

To extend the relay’s lifespan, it is important to select the appropriate relay during the design phase and use relay protection devices. Additionally, measures such as proper heat dissipation, regular maintenance, avoiding moisture and pollution, and preventing vibration and shock are all effective ways to prolong the relay’s lifespan.

It is suitable, but it is essential to choose a relay that is designed for automotive environments, ensuring it has good high-temperature resistance, moisture resistance, vibration resistance, and corrosion resistance.

Before installation, first check the relay’s appearance to ensure it is intact and the pins are not damaged or rusted. Then, use a multimeter to test the coil resistance and contact electrical properties to confirm it is functioning properly. Finally, perform a functional test to ensure the relay correctly switches the contacts when powered on.

Generally, PCB relays are not suitable for handling very high currents and voltages. If your application involves high current or high voltage, it is recommended to choose relays specifically designed for high current and high voltage, and ensure their specifications meet the requirements.

The use of relays in smart homes not only provides convenient remote control and automation features but also improves energy efficiency, enhances security, and simplifies system installation and expansion.

Our company was founded in 2007 and successfully went public in 2023, dedicated to developing innovative solutions for relays and water valves.

We accept various payment methods including credit cards, bank transfers, and AliPay.

You can purchase through our website or by contacting our sales team.

Yes, we provide a range of benefits including health insurance, paid leave, accommodation, and employee training.

Employees are entitled to paid annual leave, sick leave, and statutory holidays. The specific vacation policy may vary based on factors such as length of service and position.

If your product encounters any issues or damages, we offer product repair as well as professional technical support and training.

The product warranty period varies depending on the specific product type, but generally, it is a one-year warranty period.

We offer services including free sample delivery, product customization and development, printing customization, and packaging customization.

If you receive damaged or lost goods during transit, we will promptly contact the logistics company and assist you with the claims process. Please ensure to inspect the integrity of the goods upon receipt and promptly report any issues to us.

We strive to deliver orders on time, but in certain circumstances, unavoidable delays may occur, such as issues with raw material supply or production process adjustments. If there’s a delay in delivery, we will promptly notify you and provide appropriate solutions, such as expediting production schedules or offering compensation.

Support your OEM/ODM needs and provide one-stop customized solutions