No posts found

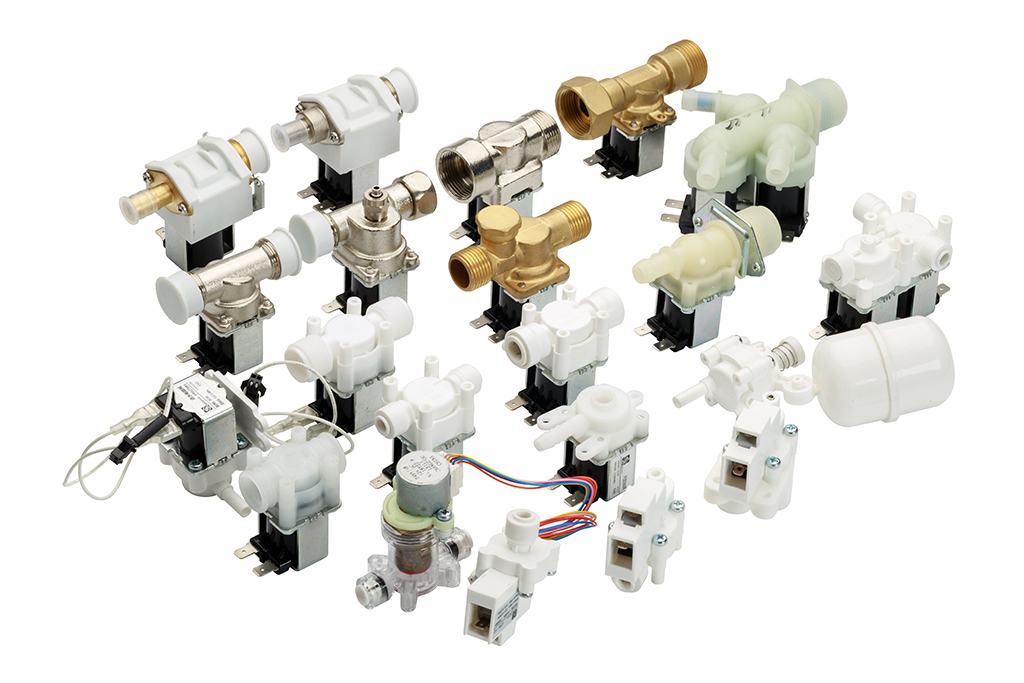

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Commitment to Excellence in Production

Commitment to Excellence in Production

It is used to monitor the pressure in piping or equipment and automatically control the start and stop of equipment (e.g., pumps, solenoid valves, compressors, etc.) through preset high-pressure (HP) and low-pressure (LP) thresholds, to realize pressure protection or automatic make-up/exhaust functions.

Tip: Use a pressure gauge to monitor the adjustment in real time, and lock it after adjustment to prevent it from loosening.

High pressure protection: When the pressure switch detects that the system pressure is too high, it cuts off the power to the solenoid valve and closes the fluid path.

Low pressure protection: when pressure is too low, disconnect the solenoid valve circuit to prevent idling or leakage.

Safety protection: to avoid overpressure damage to equipment (e.g. compressor, piping) or low pressure leading to loss of efficiency (e.g. insufficient refrigerant).

Automation control: Automatically start and stop the solenoid valve according to the pressure signal without manual intervention.

Pressure range: The set value of the pressure switch should cover the working pressure of the solenoid valve (e.g. high pressure switch ≤ solenoid valve pressure limit).

Electrical compatibility: Both voltages/currents should be the same (e.g. 24V DC or 220V AC).

Possible cause:

Pressure switch setting is wrong (higher than actual pressure).

Pressure connection clogged or diaphragm damaged.

Circuit wiring faulty (e.g. contacts oxidized).

Need to check:

Is the solenoid coil burned out.

Are the pressure switch contacts conducting/disconnecting properly.

Is the control wiring disconnected.

Adjust the pressure switch: increase the differential pressure (difference between Cut-out and Cut-in).

Add cushioning devices: e.g. accumulators or damping holes.

Check the solenoid valve response speed: too fast switching may cause pressure fluctuations.

Avoid vibration or shock.The high voltage switch is mounted on the high voltage side of the system and the low voltage switch is mounted on the low voltage side.

Our company was founded in 2007 and successfully went public in 2023, dedicated to developing innovative solutions for relays and water valves.

We accept various payment methods including credit cards, bank transfers, and AliPay.

You can purchase through our website or by contacting our sales team.

Yes, we provide a range of benefits including health insurance, paid leave, accommodation, and employee training.

Employees are entitled to paid annual leave, sick leave, and statutory holidays. The specific vacation policy may vary based on factors such as length of service and position.

If your product encounters any issues or damages, we offer product repair as well as professional technical support and training.

The product warranty period varies depending on the specific product type, but generally, it is a one-year warranty period.

We offer services including free sample delivery, product customization and development, printing customization, and packaging customization.

If you receive damaged or lost goods during transit, we will promptly contact the logistics company and assist you with the claims process. Please ensure to inspect the integrity of the goods upon receipt and promptly report any issues to us.

We strive to deliver orders on time, but in certain circumstances, unavoidable delays may occur, such as issues with raw material supply or production process adjustments. If there’s a delay in delivery, we will promptly notify you and provide appropriate solutions, such as expediting production schedules or offering compensation.

Support your OEM/ODM needs and provide one-stop customized solutions