No posts found

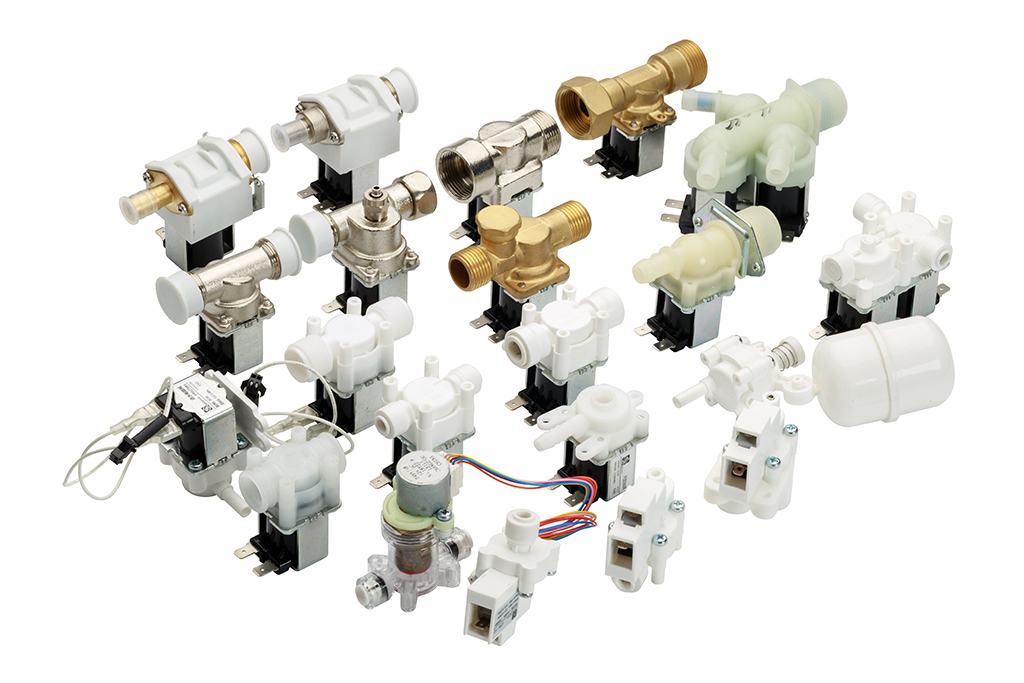

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Meishuo specializes in solenoid valves, with over 7 years of experience and 5 production lines, achieving a daily output of 35,000 units. Our main products include normally open and normally closed valves, flush valves, drain valves, and high/low-pressure switches. All our products are certified with RoHS and REACH Green environmental standards.

We are committed to providing users with excellent water quality management solutions and becoming a reliable partner for manufacturers, ensuring that each valve operates safely and reliably under various environmental conditions.

Commitment to Excellence in Production

Commitment to Excellence in Production

Normally close valves are valves that are in a closed state when no power is applied or no pressure is applied.Generally used in situations where the flow needs to be stopped when the power or gas is cut off, such as automatic fire extinguishing systems, gas leak automatic shut-off systems, etc.

*industrial automation

*HVAC systems

*fire protection systems

*liquid and gas handling

*medical equipment to control the flow of fluids or gases.

There are many factors to consider, including the working medium (such as water, oil, gas, etc.), working pressure, working temperature, flow requirements, power type (AC or DC), and installation method, etc. According to the specific usage scenario and process requirements, select the solenoid valve of corresponding specifications and materials to ensure its performance and reliability.

This depends on the material, design and sealing material of the valve. Our normally closed solenoid water valve is made of plastic, which is usually not suitable for high temperature or high pressure environments and can generally only work at room temperature and low pressure because its material has poor tolerance to high temperature and high pressure.

In the RO system, the main role of the normally closed valve is to control the switch of water flow, isolate the water source, prevent backflow, save water and energy, and improve the safety of the system. It ensures the efficient and stable operation of the RO system through linkage with other equipment.

The installation location should be convenient for operation and maintenance, and there should be enough space around it. It is generally required to be installed horizontally with the coil facing vertically upward to prevent impurities from settling and affecting the valve core movement. When connecting the pipeline, ensure that the pipeline is concentric with the solenoid valve interface and is well sealed to avoid the pipeline stress being transmitted to the solenoid valve. At the same time, clean the pipeline before installation to prevent impurities from entering the valve.

Clean the outside of the solenoid valve regularly to keep its surface clean. Check whether the connection parts are loose, and tighten them in time if they are loose. Check the condition of the valve core and sealing surface at regular intervals, clean them in time if there are impurities, and replace the parts that are severely worn in time. For solenoid valves that are used for a long time, lubricating oil can be added appropriately to ensure the flexible movement of the valve core.

The solenoid coil may be damaged and unable to generate sufficient electromagnetic force; there may be a power failure, such as insufficient voltage, line break or short circuit; the valve core may be stuck by impurities and cannot move normally; the spring may be damaged or too hard, resulting in the electromagnetic force being unable to overcome the spring force; the pilot hole of the pilot solenoid valve may be clogged, etc.

Normally open (NO) valves allow fluid to flow when the solenoid is not energized, while normally closed (NC) valves block fluid flow when the solenoid is not energized.

If the solenoid water valve has a leaking problem, first check whether the valve itself is damaged or blocked, and confirm whether the seal is intact. If replacement parts or repairs are required, it is recommended to seek professional help.

Our company was founded in 2007 and successfully went public in 2023, dedicated to developing innovative solutions for relays and water valves.

We accept various payment methods including credit cards, bank transfers, and AliPay.

You can purchase through our website or by contacting our sales team.

Yes, we provide a range of benefits including health insurance, paid leave, accommodation, and employee training.

Employees are entitled to paid annual leave, sick leave, and statutory holidays. The specific vacation policy may vary based on factors such as length of service and position.

If your product encounters any issues or damages, we offer product repair as well as professional technical support and training.

The product warranty period varies depending on the specific product type, but generally, it is a one-year warranty period.

We offer services including free sample delivery, product customization and development, printing customization, and packaging customization.

If you receive damaged or lost goods during transit, we will promptly contact the logistics company and assist you with the claims process. Please ensure to inspect the integrity of the goods upon receipt and promptly report any issues to us.

We strive to deliver orders on time, but in certain circumstances, unavoidable delays may occur, such as issues with raw material supply or production process adjustments. If there’s a delay in delivery, we will promptly notify you and provide appropriate solutions, such as expediting production schedules or offering compensation.

Support your OEM/ODM needs and provide one-stop customized solutions