No posts found

— Your Prime Source for Advanced Relays And Water Valves —

Overview:

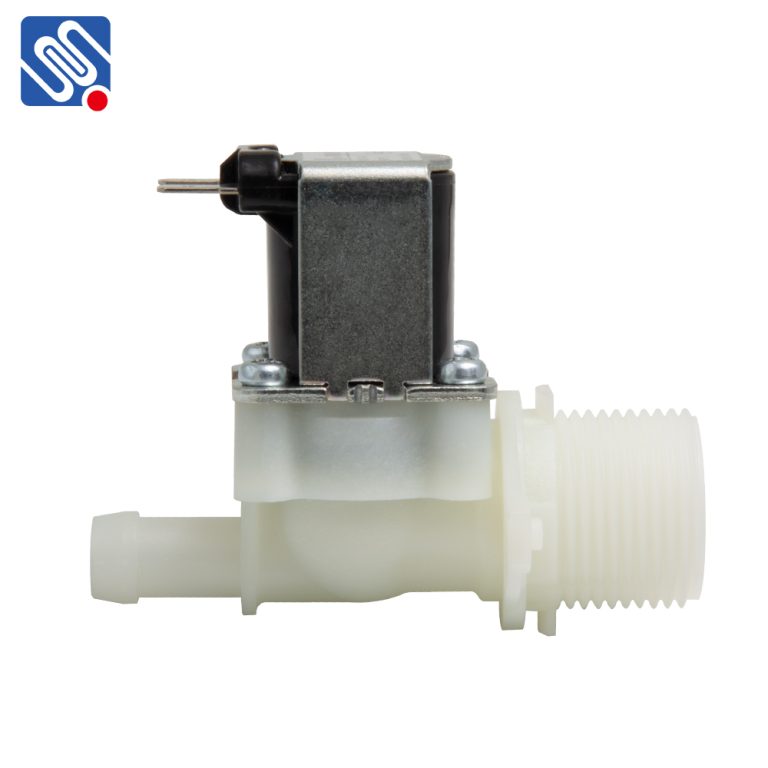

FPD180N10 inlet solenoid valve is a normally closed valve and has a relatively large water flow rate. It is usually used in Intelligent closestool, Intelligent saniatry ware and other bathroom equipment.

| Product Model: | FPD180N10 | |

| Rated Voltage: | DC12V 24V 36V AC110V 220V 50/60Hz | |

| Operate Life: | ≥100000 OPS | |

| Pressure Range | 0.02-0.8MPa | |

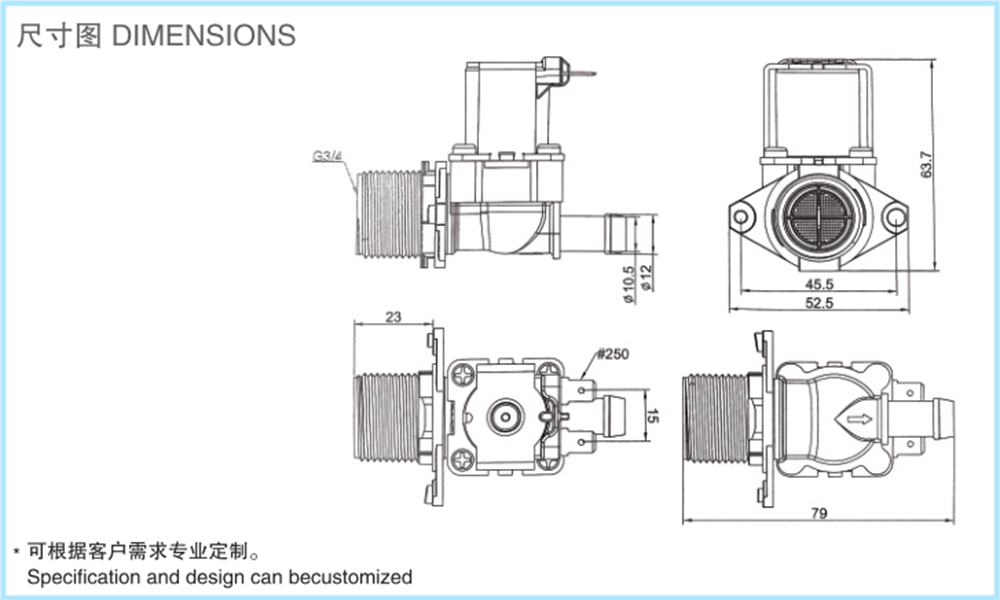

| Inlet: | G3/4 | |

| Outlet: | φ11mm pagoda | |

| Hydraulic Pressure: | 0.3MPa | 0.3-1.0MPa |

| Flow Rate: | >13L/min | >25L/min |

| Spacing: | 45.5mm | |

Product advantage

1.Clear Markings

The valve body is marked with clear inlet and outlet directional arrows, making it easy to identify and install.

2.Fine Craftsmanship

The surface is smooth without burrs, and the inner wall is finely crafted to ensure safety and durability.

3.Smooth Flow

The large diameter design ensures smooth fluid flow, reducing resistance and improving efficiency.

Company Advantages

1.Outstanding Quality

Selected premium materials, tested over 100,000 OPS to ensure durability and reliability.

2.Strict Quality Control

Standardized testing center with rigorous checks to ensure every product meets the highest quality standards.

3.Customized Solutions

Professional customization according to client requirements, perfectly suited for various equipment and environments.

4.Strong R&D Team

A skilled and innovative R&D team, continuously improving and optimizing products.

5.Efficient After-Sales Support

Comprehensive after-sales services, ensuring worry-free use for customers.

Technological process

The manufacturing process of solenoid valves includes multiple key steps to ensure product quality and performance. The partial process flow of solenoid valve is as follows:

1.Insert the lead sheet piece into the skeleton

2.Winding coil

3.Inter-turn resistance detection

4.Automatic riveting inspection of upper and lower iron plates

5.Install components such as iron core, spring, O-ring, sealing ring, etc

6.Automatic detection of solenoid valve start, seal strength, flow and electrical performance

Support your OEM/ODM needs and provide one-stop customized solutions