No posts found

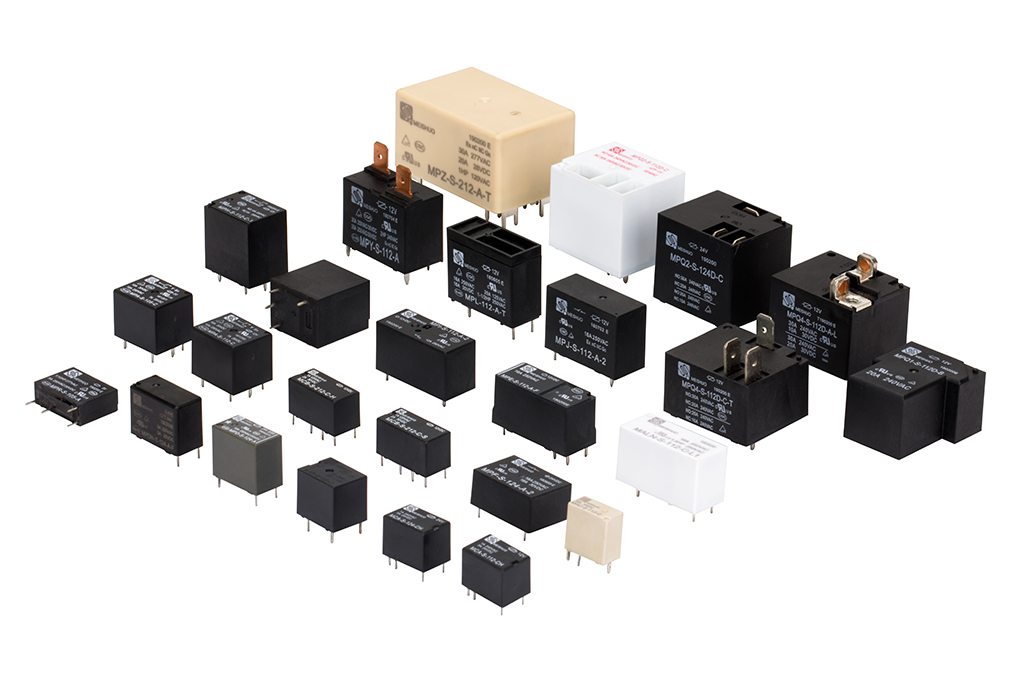

With 17 years of production experience, Meishuo is one of China’s top three relay manufacturers.

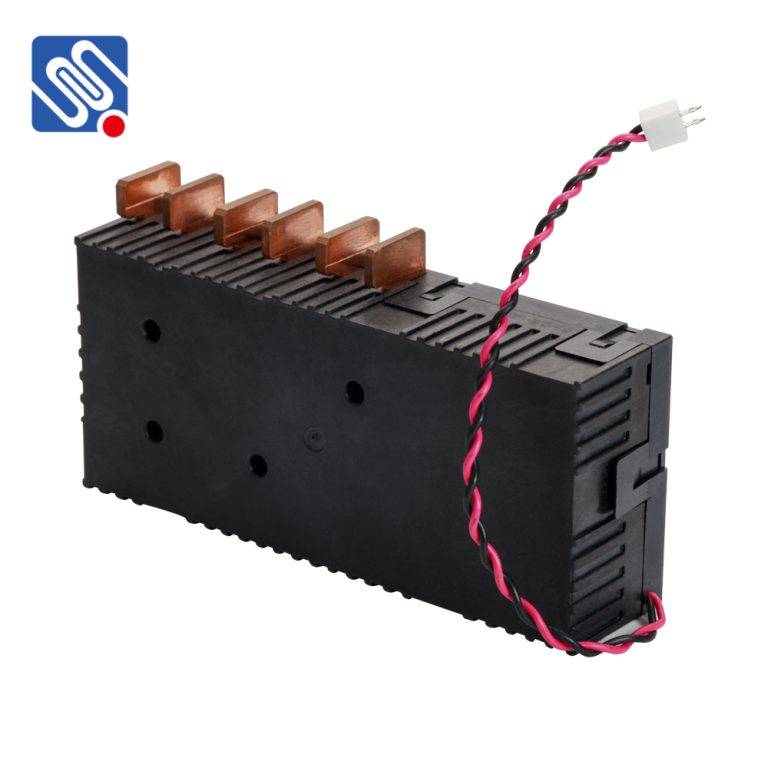

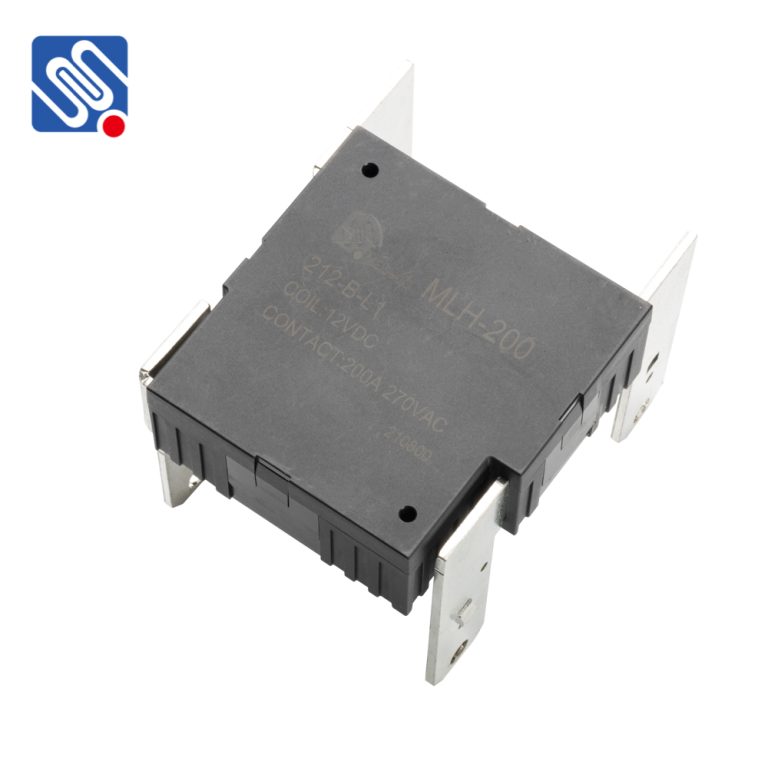

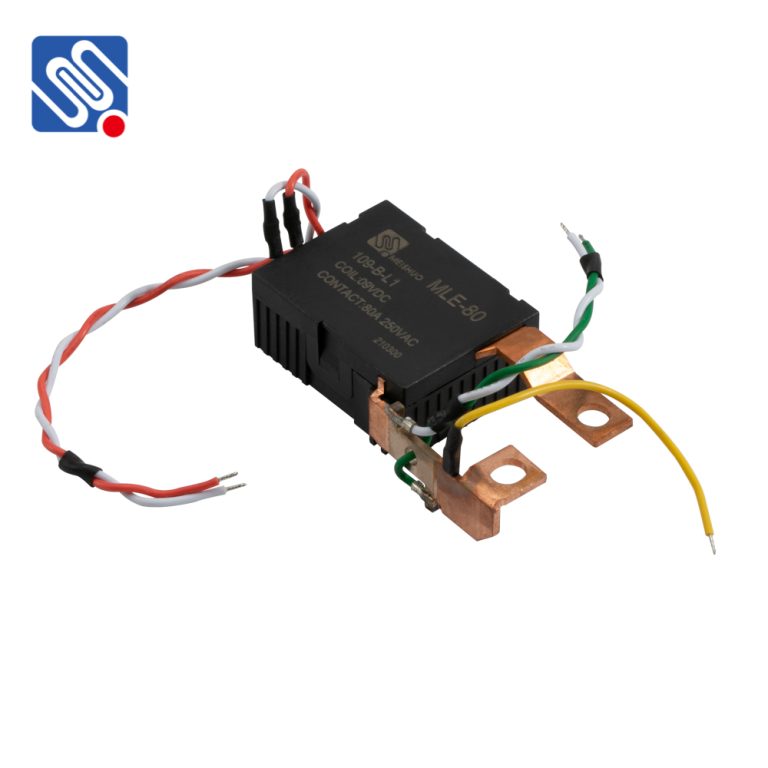

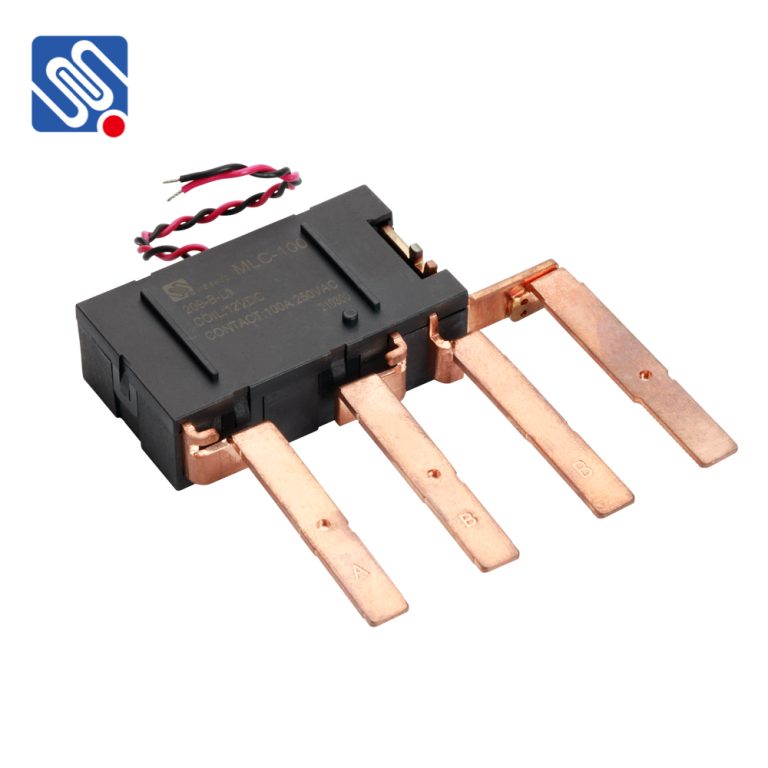

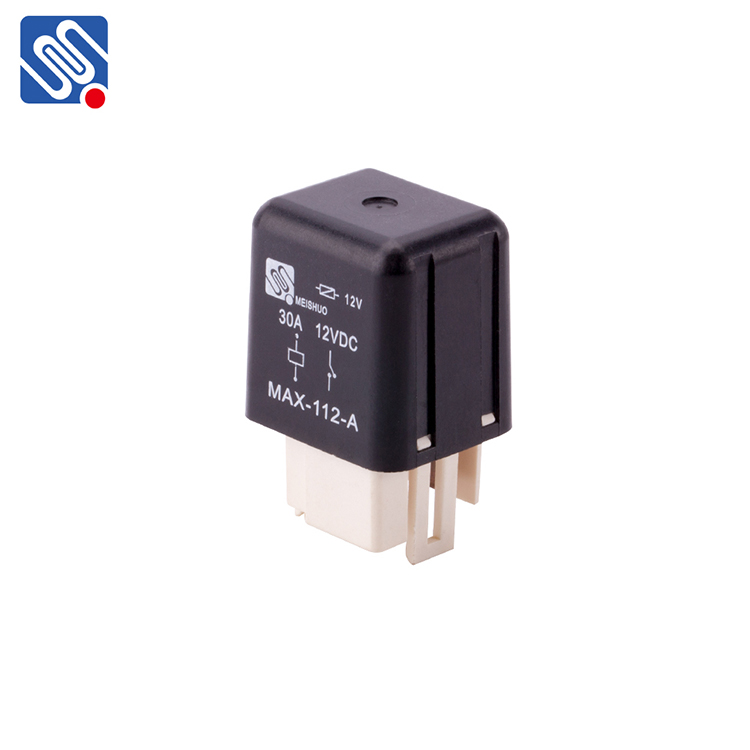

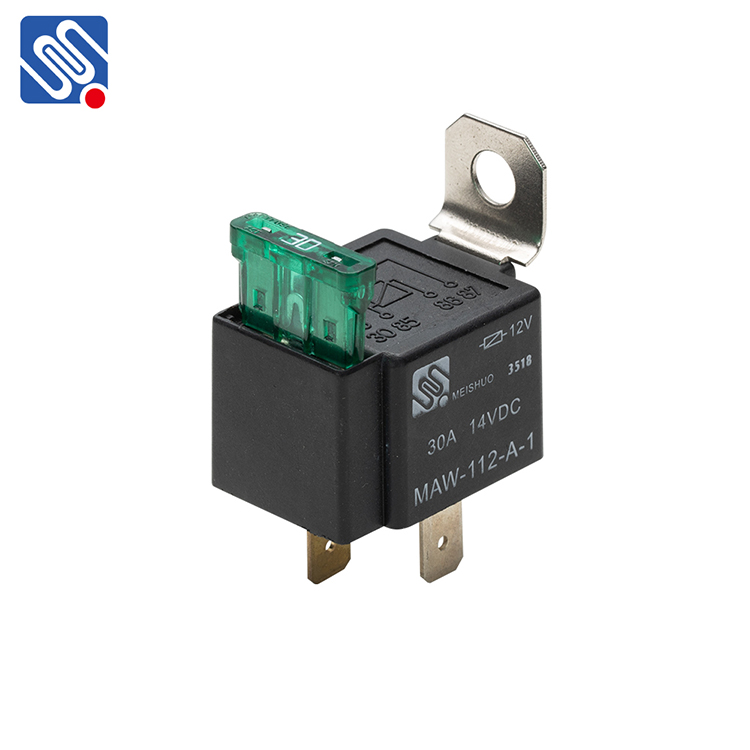

We focus on the development and manufacturing of a wide range of relays, including industrial, automotive, latching, new energy, signal, and general relays. We operate under the guiding principle of “Quality First, Customer Supreme.”

Every one of our products is certified by UL, TUV,CQC, and VDE, guaranteeing dependable quality and gaining our clients’ trust.

With 17 years of production experience, Meishuo is one of China’s top three relay manufacturers.

We focus on the development and manufacturing of a wide range of relays, including industrial, automotive, latching, new energy, signal, and general relays. We operate under the guiding principle of “Quality First, Customer Supreme.”

Every one of our products is certified by UL, TUV,CQC, and VDE, guaranteeing dependable quality and gaining our clients’ trust.

Commitment to Excellence in Production

Commitment to Excellence in Production

A relay is an electrical device used to control the switching of circuits. It allows a low-power signal to control a higher power circuit.

Load Type: Determine the relay’s compatibility with resistive, inductive, or capacitive loads, and the rated current of the load.

Rated Voltage: Choose a relay with a rated voltage greater than or equal to the operating voltage of the load circuit.

Contact Type and Configuration: Select the appropriate contact configuration, such as SPST, DPDT, and the type of contact material.

Coil Voltage and Power Consumption: Ensure the coil voltage matches the control circuit to avoid overheating or excessive power consumption issues.

Environmental Conditions: Identify the environmental conditions where the relay will be installed and used.

Size and Mounting: Choose the relay size and mounting method according to the application space and installation requirements.

Reliability and Lifespan: Consider the relay’s reliability and expected lifespan.

Electromagnetic Relays: Use an electromagnet to operate the switching mechanism.

Solid State Relays (SSRs): Utilize semiconductor devices for switching, offering high reliability and speed.

Reed Relays: Feature contacts sealed within a glass tube, ideal for low current applications.

Thermal Relays: Protect against overloads by using a bimetallic strip to break the circuit.

Time Delay Relays: Include a built-in timer to delay the switching operation.

Understand Load Requirements: Know the type of load (resistive, inductive, capacitive) and its specifications.

Environmental Conditions: Consider factors such as temperature, humidity, and exposure to dust or chemicals.

Mounting Type: Choose between PCB mount, DIN rail mount, or panel mount depending on your setup.

Durability and Longevity: Check the relay’s mechanical and electrical life ratings.

It depends on the relay type. Some relays are designed specifically for AC or DC loads, while others can handle both. Always check the relay’s datasheet for compatibility.

Single-Pole Relays (SP): Control one circuit.

Double-Pole Relays (DP): Control two independent circuits simultaneously.

Switching speed is the time it takes for the relay to open or close the contacts. It is crucial for applications requiring fast or precise switching.

Coil Resistance Test: Measure the resistance of the coil to ensure it is within the specified range.

Contact Resistance Test: Verify the resistance across the contacts when the relay is actuated.

Function Test: Apply the control voltage to the coil and observe the operation of the contacts.

Inconsistent Operation: If the relay does not switch reliably.

Burnt Contacts: Visible signs of arcing or burning on the contacts.

Unusual Sounds: Clicking or buzzing noises indicating mechanical failure.

Physical Damage: Cracks or other damage to the relay housing.

For detailed specifications, datasheets, and technical support, refer to the manufacturer’s website or contact their customer support. Many manufacturers also provide application notes and design guides.

A relay operates on the principle of electromagnetism. When current flows through the control circuit’s coil, it generates a magnetic field that attracts or releases a mechanical switch, thereby closing or opening the circuit.

Relays are used in various applications, including:

Automotive: Controlling headlights, horns, and other electrical components.

Industrial Automation: Managing machinery and production lines.

Home Appliances: Operating washing machines, dryers, and HVAC systems.

Telecommunications: Switching signals in communication networks.

If a relay is not functioning properly, follow these steps:

Check Connections: Ensure all wiring and connections are secure and correctly configured.

Test Coil Voltage: Verify that the control voltage is present at the relay coil.

Inspect Contacts: Check for signs of wear, pitting, or corrosion on the relay contacts.

Measure Resistance: Use a multimeter to measure the resistance of the coil and contacts to ensure they are within specification.

Replace if Necessary: If the relay is damaged or worn out, replace it with a suitable replacement.

Regular Inspection: Periodically inspect relays for signs of wear or damage.

Cleaning: Keep relay contacts and surrounding areas clean from dust and debris.

Testing: Perform functional tests to ensure the relay is operating correctly.

Replacement: Replace relays that show signs of malfunction or wear beyond acceptable limits.

A relay is typically used for low-power applications and signal switching, while a contactor is designed for switching higher power loads, such as motors and industrial equipment.

Our company was founded in 2007 and successfully went public in 2023, dedicated to developing innovative solutions for relays and water valves.

We accept various payment methods including credit cards, bank transfers, and AliPay.

You can purchase through our website or by contacting our sales team.

Yes, we provide a range of benefits including health insurance, paid leave, accommodation, and employee training.

Employees are entitled to paid annual leave, sick leave, and statutory holidays. The specific vacation policy may vary based on factors such as length of service and position.

If your product encounters any issues or damages, we offer product repair as well as professional technical support and training.

The product warranty period varies depending on the specific product type, but generally, it is a one-year warranty period.

We offer services including free sample delivery, product customization and development, printing customization, and packaging customization.

If you receive damaged or lost goods during transit, we will promptly contact the logistics company and assist you with the claims process. Please ensure to inspect the integrity of the goods upon receipt and promptly report any issues to us.

We strive to deliver orders on time, but in certain circumstances, unavoidable delays may occur, such as issues with raw material supply or production process adjustments. If there’s a delay in delivery, we will promptly notify you and provide appropriate solutions, such as expediting production schedules or offering compensation.

Support your OEM/ODM needs and provide one-stop customized solutions